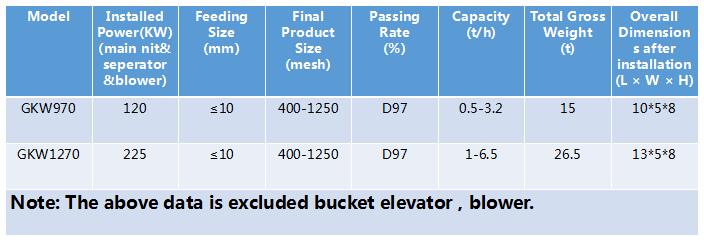

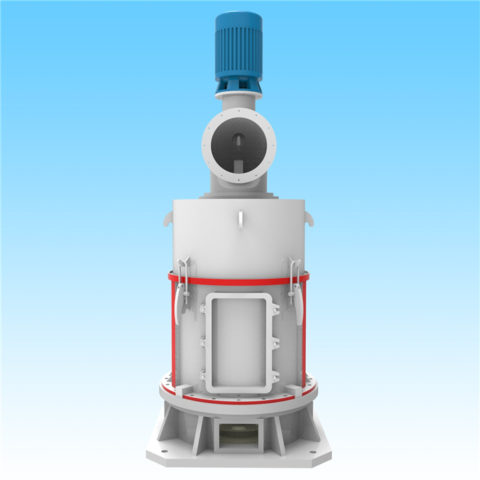

GKW970 Micro Powder Mill

GKW Micro Powder Mill is mainly used in chemical industry such as grinding glass, rubber, pesticides, enamel, paint, phosphate fertilizer, paper. Hardness below seven Moh’s hardness following humidity below 6% non-flammable and non-explosive materials. Such as: talc, barite, calcite, limestone, manganese ore, iron ore soil, chrome ore, quartz, gypsum, bentonite, etc.

Application:

GKW Micro Powder Mill is mainly used in chemical industry such as grinding glass, rubber, pesticides,enamel, paint,phosphate fertilizer, paper. Hardness below seven Moh’s hardness following humidity below 6% non-flammable and non-explosive materials. Such as: talc, barite, calcite, limestone,manganese ore, iron ore soil, chrome ore, quartz, gypsum, bentonite, etc.

System and Structure Features:

The mill consists of main frame,separator,blower,elevator,electromagnetic vibrating feeder,storage hopper,jaw crusher,duct system , pulse dust collector and electric control cabinet.Materials are broken by the crusher to particles less than 20 mm which are carried by bucket elevator up to the storage hopper .Then the electromagnetic vibrating feeder transports the crushed material at a given rate to the main frame for grinding. Under the high-pressure wind from the induced draft fan,the ground material is transferred pneumatically to the separator above the main frame where it is separated.Coarse particles fall back down to the mill for regrinding.The qualified particals go into the collector where the final products will be removed through the discharging outlet. The purified air flows to the air blower through the pipe above pulse dust collector. Air flue is open circuited type. Air stream in all pipelines flows with negative pressure except the air blower, which improves the working environment in the workshop.

Working Principle:

After conveyed into the grinding mill by screw conveyor,the raw material has to be introduced into the grinding zone in front of the rollers with the aid of the plough blade. The grinding function is realized by the centrifugal forces which act on rollers.

Main Technical Features:

1.Wide range of material processing,Currently in China GKW micro powder mill is the grinding mill with widest range of processing non-metalic mineral stone for 400mesh -1250 mesh .

2.Low cost for wearing part.

3.More convenient for maintenance and changing wearing parts.

4.Low unit power consumption, creating better economic benefits for users.