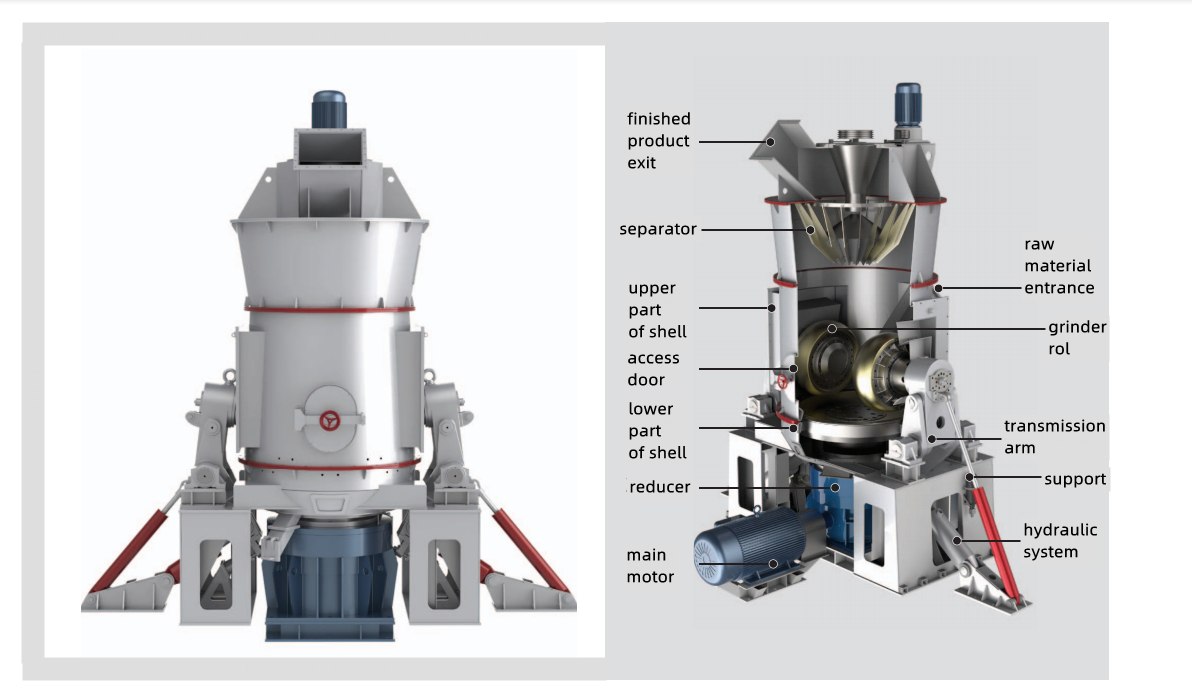

GKLM series Vertical Roller Mil

Vertical roller mill are suitable for huge capacity producing, widely used in grinding non-flammable and non-explosive materials under 7(the Moh's hardness), such as quartz, feldspar, calcite, talcum, barite, fluorite, iron ore, copper ore quartz, especially for slag, cement clinker, zircon sand, fly ash and carborundum, coal, etc.

Based on the absorption of advanced technologies of famous International Corporation and with more than

40 years’ experience in grinding mill production, Guikang has launched the GKXLM Vertical Mill which integrates

drying and grinding with high efficiency and energy saving.It can be widely used in cement, metallurgy chemical industry,

non-metallic ore, non-ferrous metals ore powder grinding, electric power and othe areaused in grinding of raw cement,

clinker(slag), coal, gypsum and pyrophyllite, square corner stone, quartz, zinc, yi, tin and other mineral materials.

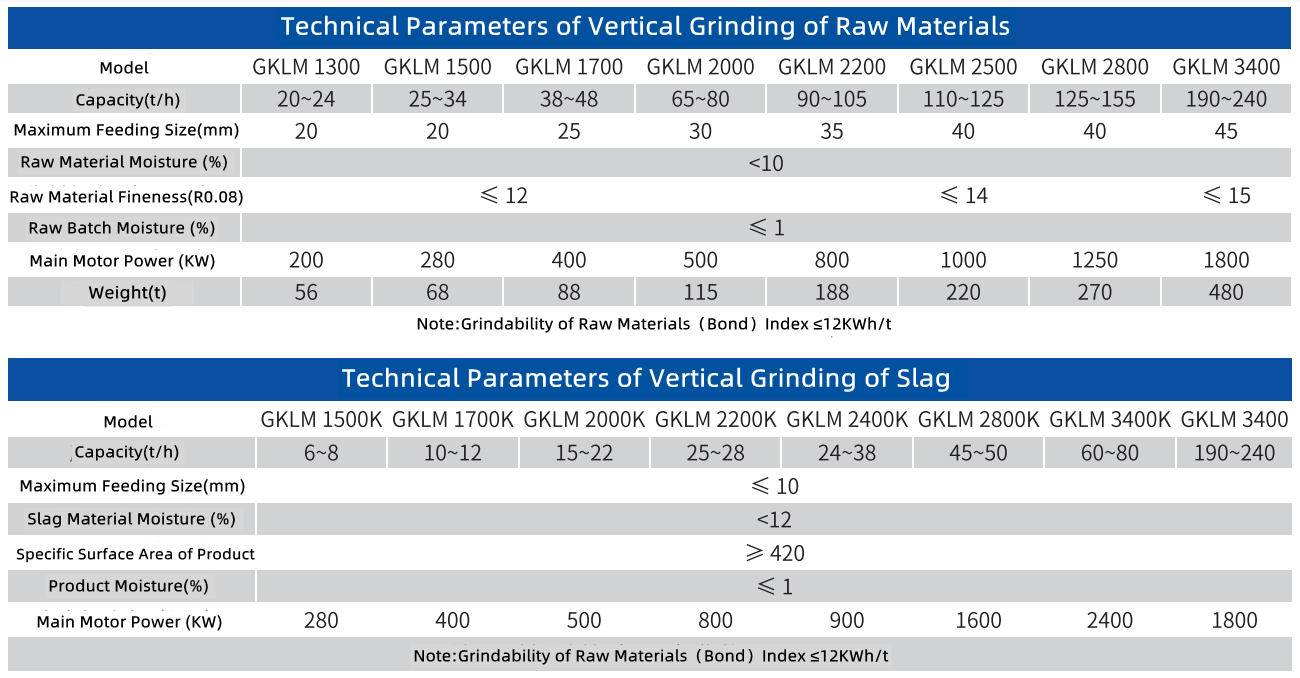

Technical Parameters

Technical Features

1.Low Cost: High efficiency and low power consumption. It consumes 40 to 50 percent less power than a ball mill. Grinding wheel and disc with special materials, less wear and long service life, reduce operating costs;equipped with an external circulation device to further reduce power consumption.

2.Low Construction Cost: Compared with the vertical mill and ball mill system, the land area can be reduced by 50%, and the construction cost can be reduced by about 70%. Due to the combination of crushing, drying, grinding, grading and transportation, the system is simple and can be arranged in the open air, so the construction cost is low.

3.Easy and Reliable Operation: Equipped with automatic control device, remote control can be realized, simple operation; Equipped with a limit device to prevent the grinding spoke from contacting the liner, there will be no destructive violent vibration.

4.Easy Maintenance: By overhauling the oil cylinder overturning grinding wheel assembly, grinding wheel and disc can be replaced in a very short time.

5.Less Pollution: Small vibration and low noise, the system is in negative pressure operation, no dust overflow.

6.Stable Product Quality:The materia stays in the mill for a short time, easy to detect and control the product powder and chemical composition.

Case Pictures