The advantages of GUIKUANG’s calcium hydroxide production line can be summarized as follows:

High Degree of Automation:

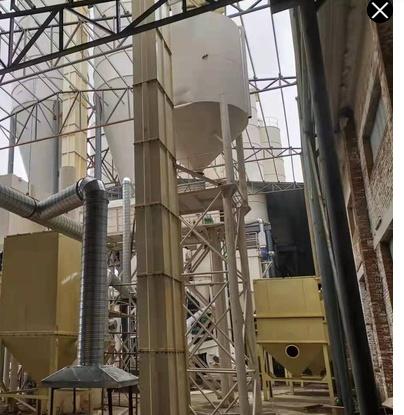

Raw materials, finished products, and waste residues in the production line are fully handled without touching the ground, using pulse negative pressure conveying, reducing manual operation and improving production efficiency.

Intelligent central control allows for one-click or zonal start-up, with automatic shutdown and fault alarm functions, making operation simple and easy to learn.

Efficient, Energy-Saving, and Environmentally Friendly:

The production line utilizes advanced energy-saving equipment and optimized processes, effectively reducing energy consumption.

It is equipped with comprehensive tail gas treatment devices capable of purifying exhaust gases generated during production to meet environmental protection standards.

Techniques such as pulsed water mist dust removal and heat recovery utilization further enhance environmental performance.

Product Diversification:

The production line can produce various specifications of calcium hydroxide products to meet the needs of different customers.

By adjusting process parameters, customized production can be achieved to satisfy the personalized needs of different industries.

High-Quality and Stable Products:

The production line employs precise dosing systems and strict quality control measures to ensure that the produced calcium hydroxide products are of high purity and uniform fineness.

Rigorous inspection systems and electronic means for rigid testing guarantee the stability and consistency of product quality.

Furthermore, GUIKUANG’s calcium hydroxide production line may also offer other advantages, such as reduced labor costs due to the central control system that minimizes manual operation, and high efficiency in the lime slaking process achieved through the use of hot water, which accelerates the reaction rate. These advantages collectively make Guilin Mining Machinery’s calcium hydroxide production line highly competitive in the market.